Effects of a plant breakdown on implemented integrated planning

The following UseCase shows how the example company “Ideal” uses integrated planning to manage bottlenecks:

Company “Ideal” is an aluminium rolling mill and produces aluminium coils for further processing.

One of the cold rolls is out of operation.

The subsequent process steps of the order-to-cash process (E2E) are endangered. In order to get the holistic interlinked process running again continuously, “Ideal” uses various planning solutions from bisonaire and partner systems so that the negative effects of a plant breakdown can be cushioned in the short, medium and long term.

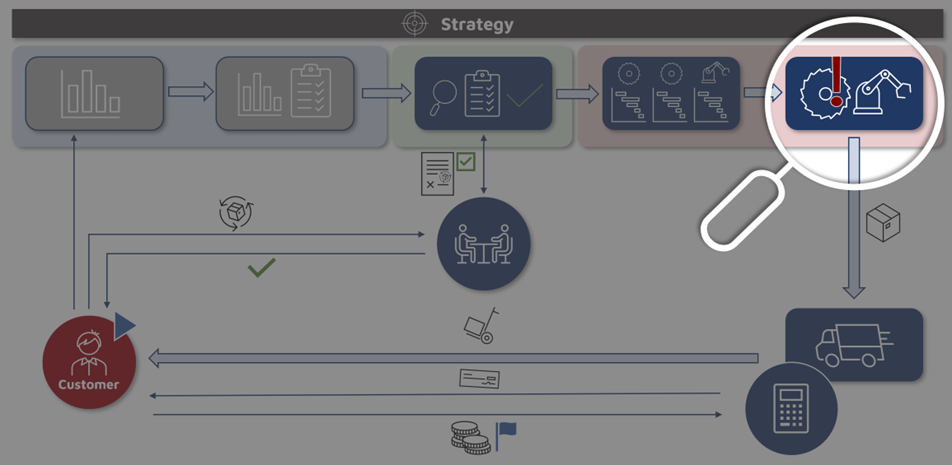

Operational planning level

A defect has occurred on a cold roll. This problem can be solved by an internal technician within the next two hours.

Which plant will take over production during this time? Which products can continue to be manufactured? Which urgent orders have to be transferred to other plants?

These questions can be answered by the operational planning of the next two hours, because “Ideal” uses a live planning solution: The DELMIA Scheduler reschedules the queued production orders so that there are no delivery bottlenecks or downtimes of the interlinked plants. The scheduler optimally solves the problem of the nonoperating plant at the operational planning level.

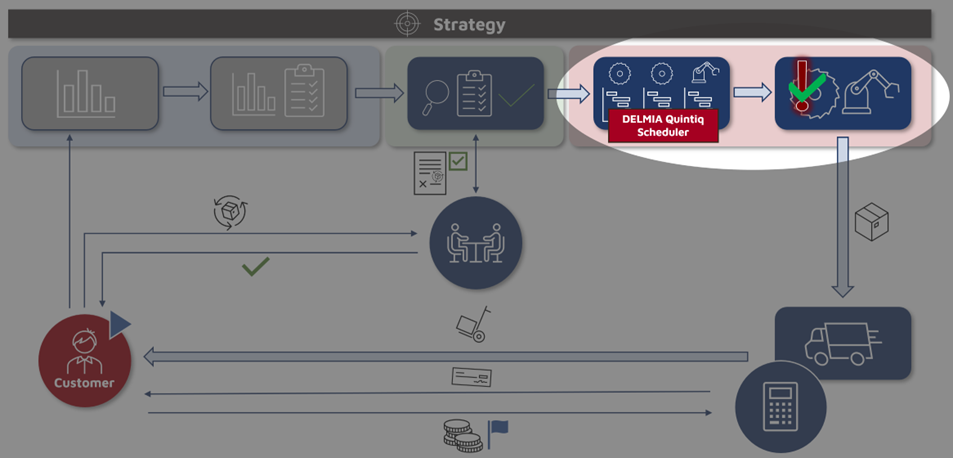

Tactical planning level

However, in case the technician has to order a plant component externally and the plant can only be put back into operation in two weeks because of delivery problems of the component, new planning must be carried out in the medium term. Due to the plant breakdown, a backward linkage of the new planning activities takes place so that the order-to-cash (E2E) process can continue to run productively.

Tactically, the production of the next two weeks must be rescheduled. In addition, when checking the feasibility of new orders, the breakdown of the plant is also considered, and the orders are given new delivery dates.

This tactical planning is applied by the DELMIA Company Planner using Live Planning.

The process quality of “Ideal” can be kept high through tactical planning despite the plant breakdown. The changes to the delivery dates can be communicated and customer satisfaction is ensured.

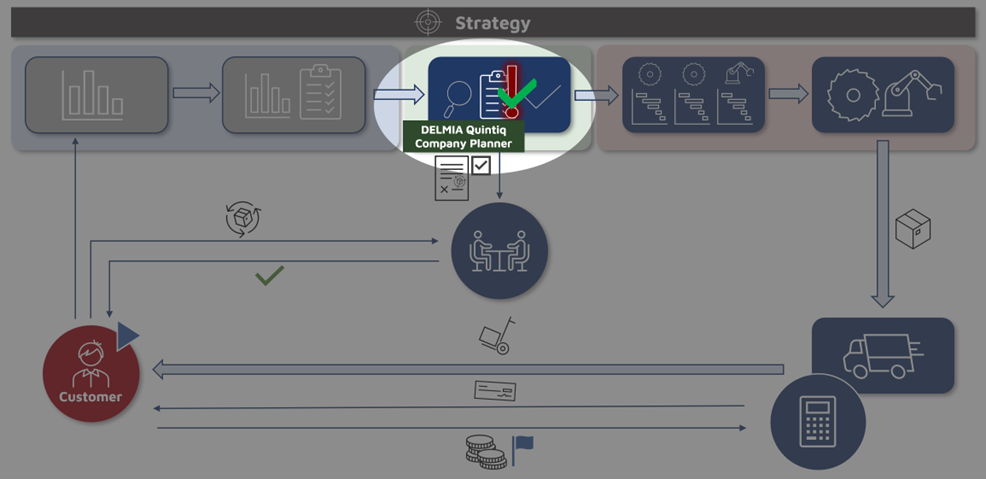

Strategic planning level

After two weeks, the system cannot be put into operation despite the new component, as there is serious damage to the unit. A new plant is needed. The new plant has a delivery time of one year. It will therefore be out of production for a long-term period.

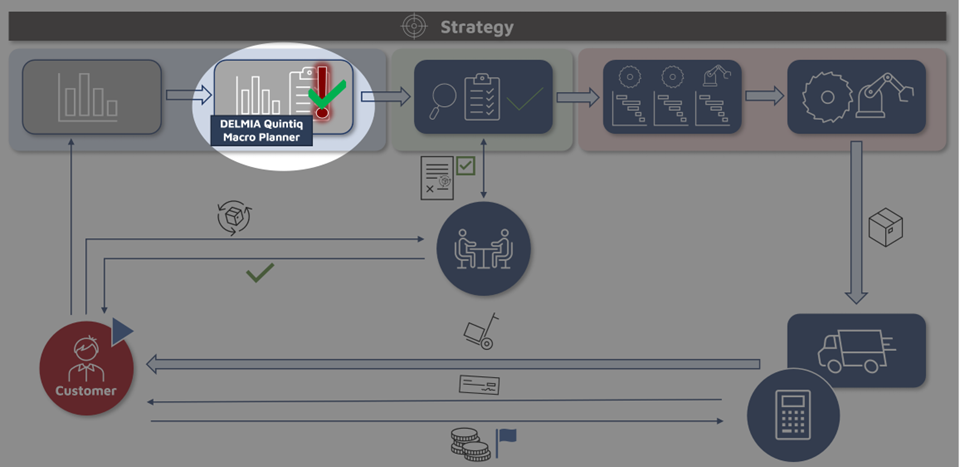

Orders have already been tactically planned for the next few weeks, but in this case the planning puzzle that needs to be solved extends further into the future. It must now be strategically planned whether the forecast sales can be realised with the remaining plant capacity according the demand forecasts. This is where strategic planning and review of plant capacity become urgently necessary.

“Ideal” can also meet this challenge with bisonaire’s planning solution, the DELMIA Macro Planner.

How integrated planning minimises the negative consequences of production bottlenecks

The holistic planning that “Ideal” implemented in collaboration with bisonaire, cushions the negative consequences of operational plant breakdowns across planning levels. By seamlessly integrating planning across levels, this implementation enables optimal planning and continuing production and the order-to-cash process, even under difficult circumstances.

Holistic planning enables companies to operate efficiently and smoothly despite bottlenecks, ensuring long-term process quality, strengthening customer relationships and consolidating the company’s success.

By minimising the negative consequences of operational plant breakdowns, integrated planning is a valuable component of robust business operations that meet the demands of the modern business world.

How is your company equipped in terms of integrated planning?

Can you overcome the hurdles of plant breakdown through planning?

With bisonaire’s integrated planning solution (and partner systems) you can.