Fraport

💪 We are proud to make a decisive contribution to the aviation industry by supporting Fraport AG – a leading global airport operator – in their winter service.

🛫 Fraport AG, known for its presence at 28 airports on four continents, is committed to the motto “Have a good trip! We make it happen.” This vision is lived both at Germany’s largest air traffic hub in Frankfurt and at its global locations.

Our services for the development process enable efficient scheduling of winter services, including the coordination of staff, training, certifications, personnel planning, and the allocation of clearing vehicles.

Our dedicated #bestteamontheplanet of developers, consultants, and project managers independently ensures that this product not only runs smoothly and is highly available but is also continuously developed, quality-tested, and updated for innovations.

It’s great to see that our work contributes to people being able to travel safely from A to B under difficult winter conditions – whether it’s for business appointments or to visit distant family members. We are grateful for this partnership opportunity and look forward to the ongoing successes and innovations that emerge from this collaboration. 🙏

Speira

🌟 We’re thrilled to announce Speira has chosen our #bestteamontheplanet here at bisonaire to redesign and implement their E2E integrated planning process. We’re embarking on a comprehensive transformation of Speira’s operations, streamlining their end-to-end processes and enhancing the Order to Cash cycle to improve efficiency, cash flow, and customer satisfaction. Our focus on integrated planning and optimization will ensure a dynamic, waste- and CO2-reducing strategy that elevates service quality across their supply chain.

🌍 About SPEIRA:

Speira is a leading European aluminium rolling and recycling company, comprising a total of eleven recycling and production sites in Germany and Norway. Speira recycles up to 650,000 tons of aluminium per year and produces around one million tons of advanced rolled products. The plants include the Alunorf joint venture, the world’s largest aluminium rolling mill, and Grevenbroich, the world’s largest refining plant in the world.

🎯 Our project goals with Speira include refining various KPIs and improving overall process quality, alongside reducing inventory to better cash flow and waste management. We’re also focused on updating their planning systems with advanced IT solutions and creating a digital supply chain twin to streamline decision-making and support CO2-optimized planning.

OETINGER Aluminium GmbH

🌟 First SME project with OETINGER Aluminium GmbH! We are opening a new chapter in the history of bisonaire! Previously known for our successful collaboration with global players in the metal industry, we are now expanding our horizons and bringing our expertise to the dynamic world of SMEs.

🛠️ Our goal is to support Oetinger Aluminium in optimizing and digitalizing their production and planning processes to increase efficiency, sustainability and competitiveness. We are convinced that our experience with large corporations combined with the agility and innovative strength of SMEs will lead to exceptional results.

🤝 This project is not only proof of the trust that Oetinger Aluminium places in us, but also a sign of our commitment to providing customized consulting and software solutions for companies of all sizes.

LIBERTY Galati

🎉🚀 We’re thrilled to announce that LIBERTY Galati has chosen our team at bisonaire to upgrade all their DELMIA Quintiq Systems. The current Quintiq release offers many improvements and new features introduced in the 2020, 2021 and 2022 versions. These include a more modern user interface, significant performance improvements, easier implementation and integration, improved security, and much more. It’s always a pleasure to see companies that are already among the top continue to improve.

🌍 About LIBERTY Galati: 🌍

LIBERTY Galati is the largest integrated steel producer in Romania with a capacity of 3 million tons per year. With a rich history, LIBERTY Galați set off – more than 55 years ago – with ambitious plans to be the main steel supplier for Eastern European countries. Today the steel company has an even more ambitious plan – to produce green steel, following the global vision of LIBERTY Steel Group.

It’s impossible to imagine modern life without steel. It is an essential ingredient of our society’s growth and prosperity. From the materials it is made of, all the way to the buildings, bridges, cars, planes and all the other everyday items that we take for granted, steel is all around us.

LIBERTY Galati is implementing a series of strategic automation and digitization projects and the partnership with bisonaire is part of this process. To achieve their level of excellence, they use – among other tools – DELMIA Quintiq. With support ending for older versions, LIBERTY Galati has chosen to upgrade their systems with Bisonaire’s expertise. We’re excited to contribute to LIBERTY Galati’s ongoing success! 🔥

Novelis

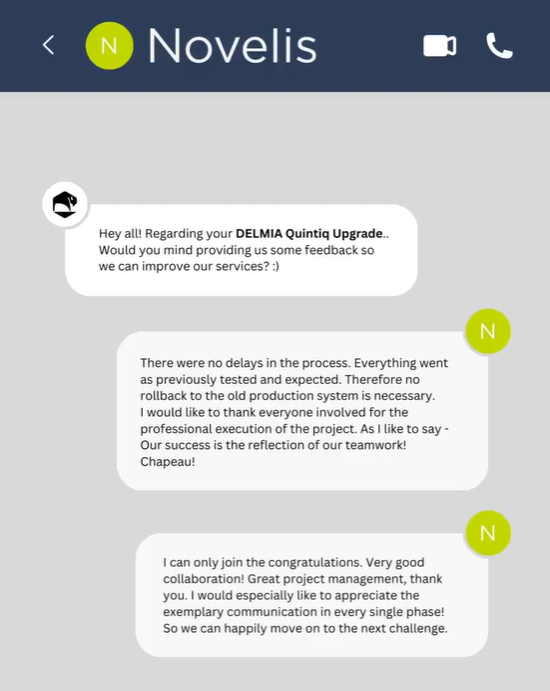

🏅 Novelis upgraded their DELMIA Quintiq Applications with us – and you should too!

Novelis is the leading producer of flat-rolled aluminum products and the world’s largest recycler of aluminum. They provide innovative solutions to the aerospace, beverage can, automotive and high-end specialty markets. Operating an integrated network of technically advanced rolling and recycling facilities across North America, South America, Europe and Asia, Novelis leverages its global manufacturing and recycling footprint to deliver consistent, high-quality products around the world. At Novelis, everyone of the 14k+ employees is driven to produce excellence.

To achieve their level of excellence, they use – among other great tools – DELMIA Quintiq. Since DELMIA announced EOL for support of older versions (below v6.0) Novelis decided to upgrade their DELMIA Quintiq scheduling solution with the help of bisonaire. We’re thrilled to share their feedback on the whole project – from planning to execution it was a smooth experience working together!

Fachzeitung Produktion

Managing Director, Partner, COO @bisonaire.com and also a talented speaker. Daniel Steitz talks about how to realize your digital-ecological transformation – because the energy and resource transition affects all industries!

Aluminium Norf GmbH

Thanks to the “Batch Intelligence System”, Alunorf saves around 500,000 tons of CO₂ along the value chain. This is a great step towards more sustainable raw material production. 🌱

We are proud to have successfully built the “brain” of intelligent and fully automated batching and charging with our #bestteamontheplanet and the super Aluminium Norf GmbH – Alunorf team 💪