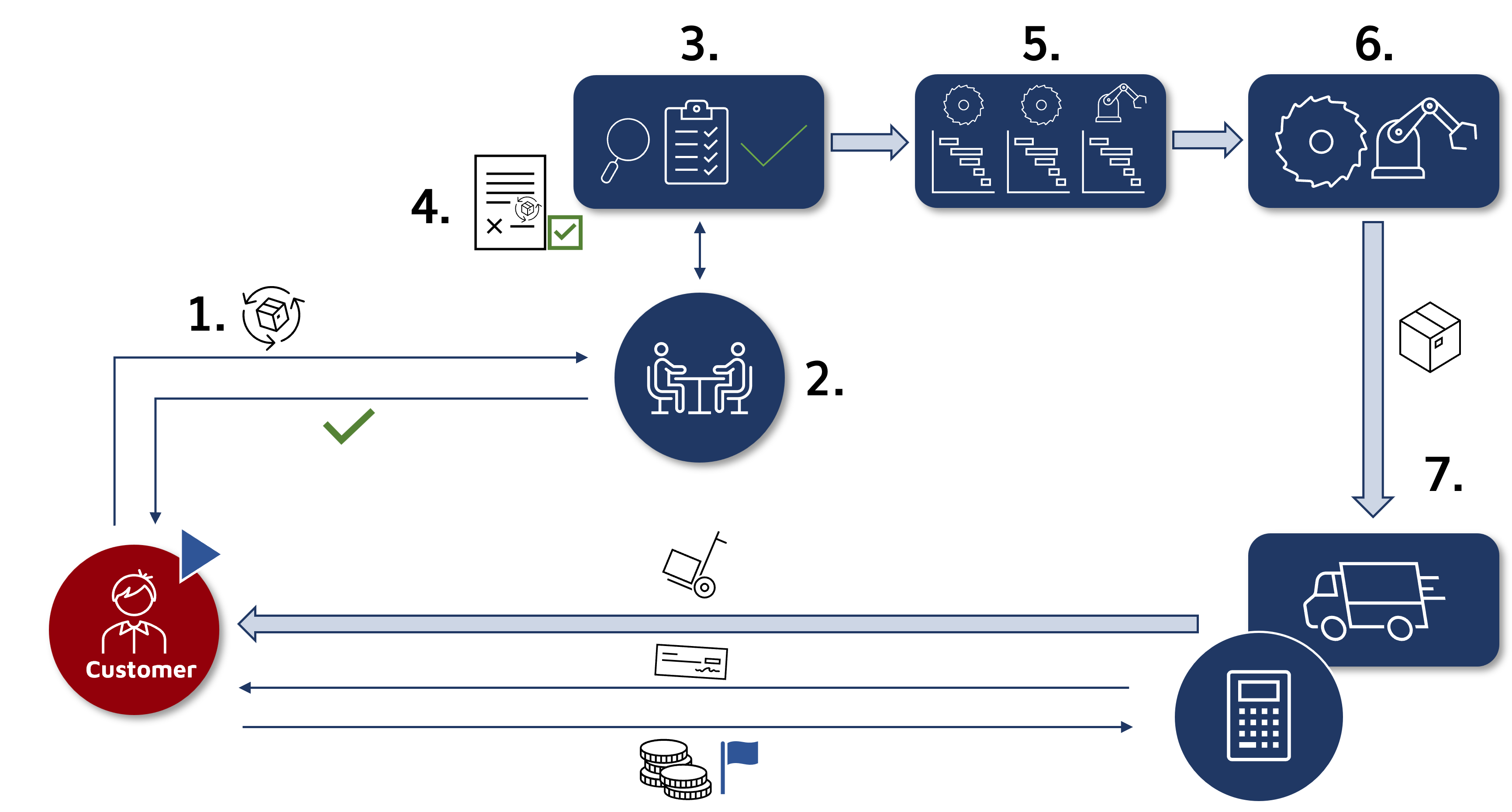

How is the order-to-cash process structured?

Your business can be mapped on an abstract level to the following core processes:

- Your customer places an order, which is received by the sales team.

- Your sales team releases the information about the order to check its feasibility.

- A check is made (tool-supported) to determine whether the production of the order is feasible. If there are any feasibility conflicts, purchase order details (e.g., delivery date) are adjusted.

- The information about the adjusted order is passed on to the customer via the sales department.

- At the same time, the matching production order is optimally planned in production planning (by Live Planning).

- Based on the (optimally) planned production manufacturing proceeds.

- The completed products are delivered to the customer on time via the logistics department, so that your satisfied customer after invoicing settles his bill and you receive the payment promptly.

The tactical and operative planning for the daily business and the described core processes are the relevant basis for a successful business for any manufacturing company.

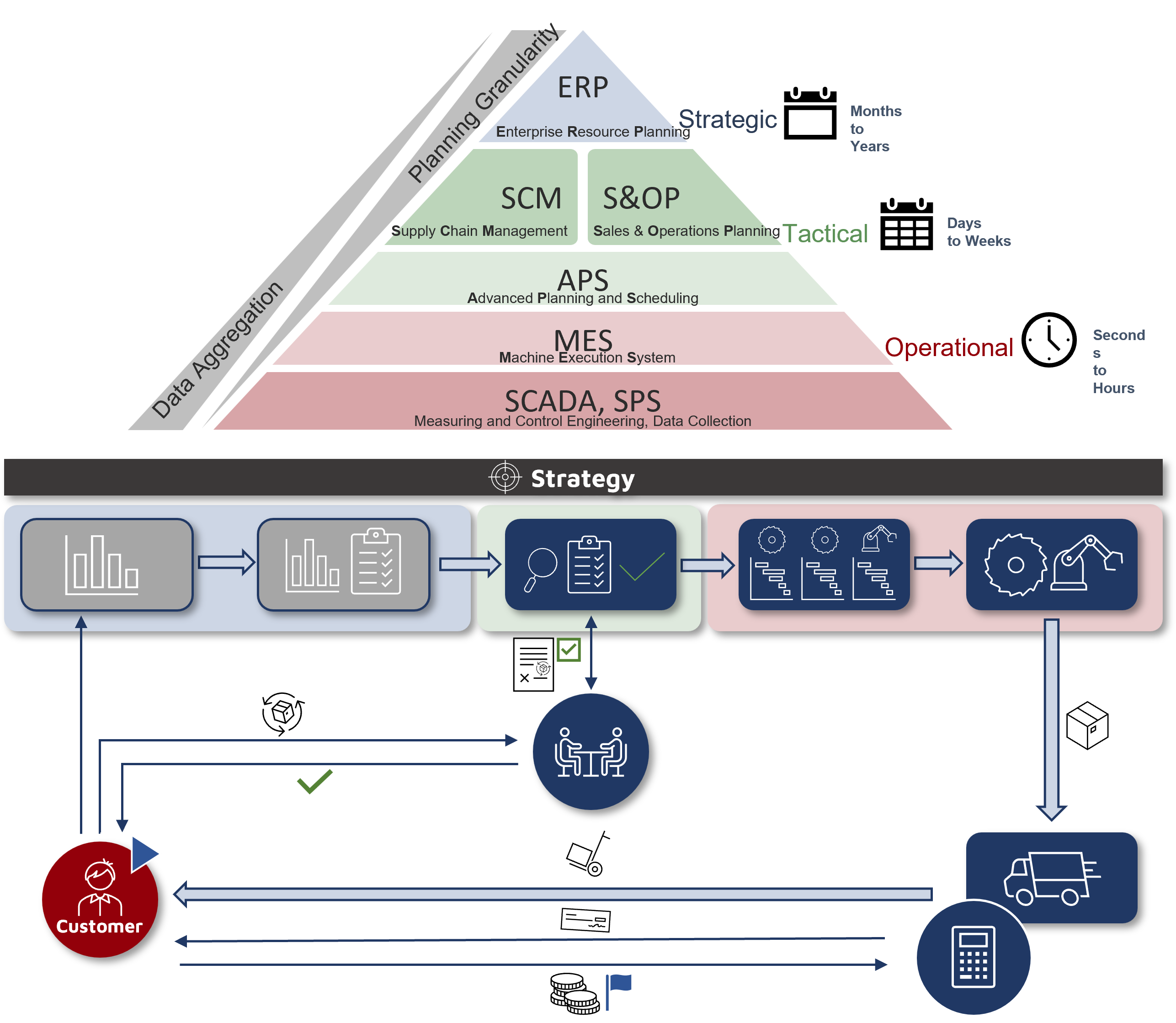

Which levels of the end-to-end planning process optimally support the order-to-cash process?

In addition to short-term planning (minutes-hours) and medium-term planning (days-weeks) , you also need to take a long-term view (months-years) of your company into account. The three relevant levels can be divided as follows:

Strategic planning, tactical planning and operational planning.

Corporate strategy influences every process and dictates the path the company takes. Strategy adjustments, such as energy or CO2 demand reductions due to emission restrictions, provide great leverage for planning activities so that strategy implementation succeeds.

Demand forecasts, such as “future demands”, are strategically planned and need to be reviewed against future available capacity and materials, so that sales budgets are then available for your accurate day-to-day planning. (see above)

Tactical and operational planning processes aligned with the strategy take place in such a way that day-to-day business can be handled optimally, which means with high efficiency and maximum results.

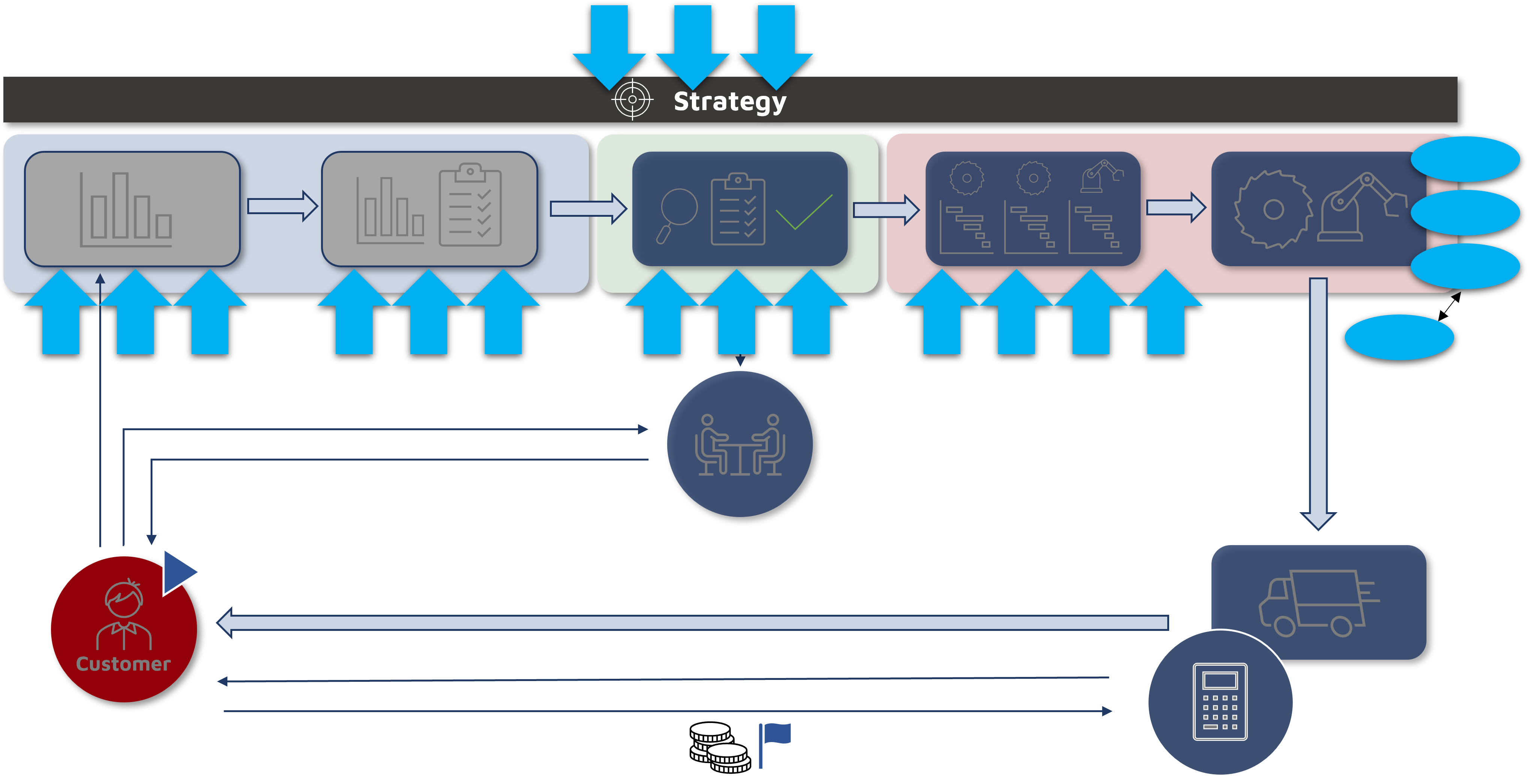

Why is end-to-end integrated planning necessary?

Implementing end-to-end planning is important for your company because it allows you to plan the order-to-cash/ E2E planning process and thereby optimize it. You ensure higher process quality by increasing transparency, which significantly increases customer satisfaction.

The holistic consulting approach with suitable system solutions by bisonaire offers you exactly these advantages and helps you to achieve your business goals transparently and quickly with live planning.

In integrated planning, an incredible number of internal factors play a role, which significantly influence the planning of processes, such as workforce, plant capacity and work schedule. In addition to those factors, one of the main challenges of a company is the continuous improvement process in the context of LEAN production and LEAN administration (Deming cycles – CIP). It must be synchronously planned-done-checked-improved (PDCI) in both small and large control loops across planning levels.

In order to include this multitude of aspects and challenges precisely and completely in the planning, a systemic, digital and holistic planning solution is THE suitable way to plan your processes consistently.

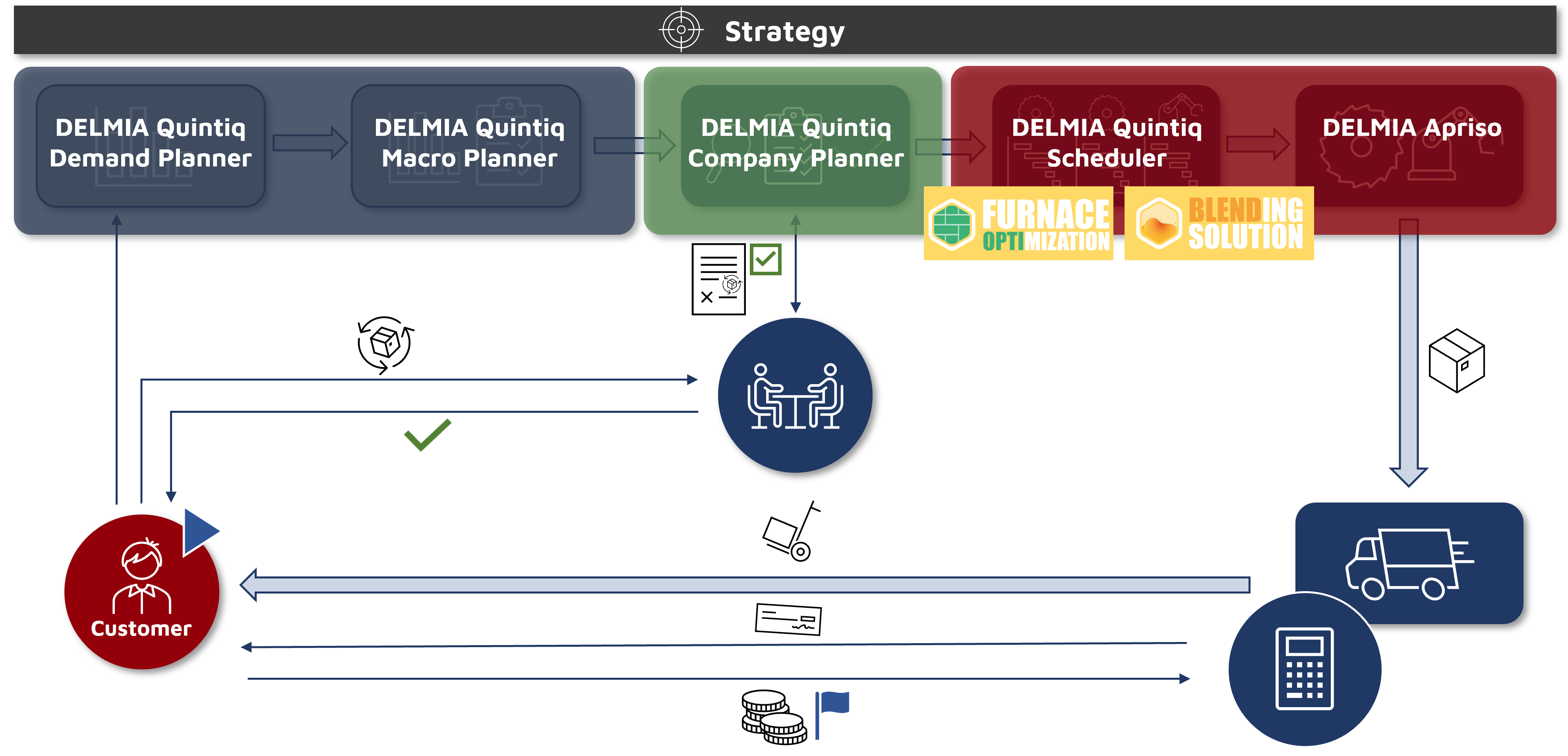

Which digital and automated solutions should be used for holistic and integrated planning across the 3 planning levels?

Strategic planning:

DELMIA Quintiq Demand Planner optimizes demand and sales forecasts.

DELMIA Quintiq Macro Planner handles global, integrated planning for you, taking into account all aspects of your business – from capacity planning to sourcing strategy – and is aligned with your long-term business goals, demands and sales forecasts.

Tactical Planning:

DELMIA Quintiq Company Planner verifies that it is feasible to manufacture the order and reschedules existing production orders so that all orders can be manufactured. Integrated production and material planning with digital, automated order acceptance takes place.

(For example, by adjusting delivery dates and transparently communicating early delivery date changes back to the customer.)

Operational Planning:

DELMIA Quintiq Scheduler handles concrete plant scheduling with “Sequenze Optimization” to optimize your production processes and make efficient use of resources.

The bisonaire Blending Solution calculates global solutions for planning the complex composition of your batches in the foundry using a sophisticated optimization algorithm.

The bisonaire Furnace Optimizer plans the optimal use of your furnaces. It allows you to consider different parameters such as furnace size, annealing time and temperature in the optimization. This enables you to create intelligent batches for the furnace and then plan an optimized sequence on the line.

(Operational) Production Level:

DELMIA Apriso enables you to fully integrate your “Manufacturing Operations” by using the MES/MOM solution. Here, fully integrated planning and scheduling of all production processes, including MES/MOM feedback as well as automated optimization and feedback calculation are just a some of the many advantages in working with a fully-integrated MES/MOM solution provided by Apriso.