Where does the Blending Solution fit in?

bisonaire Blending Solution is aimed at manufacturing companies that mix several materials to form finished products and can act in a recipe-variable manner. This means that the target composition of the finished product (alloy) is subject to certain tolerances, and that the input materials have individual compositions. bisonaire Blending Solution was developed for casting processes in the metalworking industry in order to combine different input materials in an optimized way to form a target alloy.

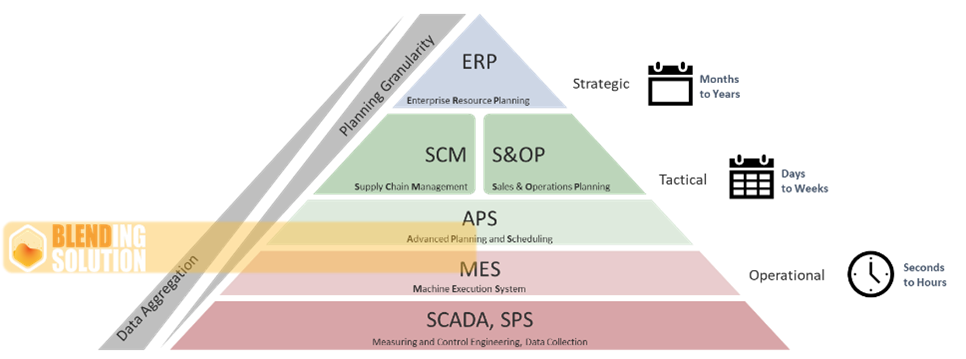

In the context of different planning levels and our vision at bisonaire, we distinguish between the strategic, tactical and operational levels. bisonaire Blending Solution, as an advanced planning tool, starts between the tactical and operational levels. In the system landscape of your company, bisonaire Blending Solution fits in between the APS and MES and communicates in both directions.

When does this product make sense for you?

Do you have a lot of effort to combine different input materials with different compositions into one batch with one target alloy?

➡️ Complex planning puzzle, which can only be solved with a great deal of manual effort.

You use a lot of pure material to meet your target alloys in the melting furnace?

➡️ Your use of pure material leads to high costs and a bad CO2 balance for the entire company.

The composition of your batches in the foundry are not fully transparent and retrospectively traceable and you cannot guarantee that certain batches were only cast from certain inputs, such as recycled material?

You cannot react fast enough to changing conditions in production or storage situation and cannot adjust the old planning ad hoc?

You would like to save storage processes of scrap and thus time and money by placing them directly into suitable batches?

Your warehouse management is not coordinated with planning, resulting in long transport routes and more complex planning regarding the accessibility of materials?

Why is the product useful for you?

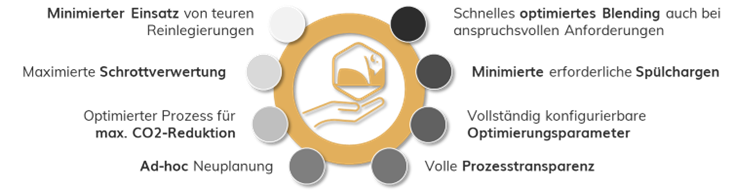

The bisonaire Blending Solution as your individualized batching software supports you …

– Enable fast & KPI driven batch planning even under complex circumstances

– Maximize the use of scrap in your alloys

– Reduce the amount of expensive pure metals used

– Reduce your CO2 footprint

– Respond quickly to changes in your production conditions

– Make your planning more transparent

– Reduce the number of purging batches in your foundry

– Ensure the use of recycled material for certain alloys and be able to prove it more transparently

How does the product create your benefits?

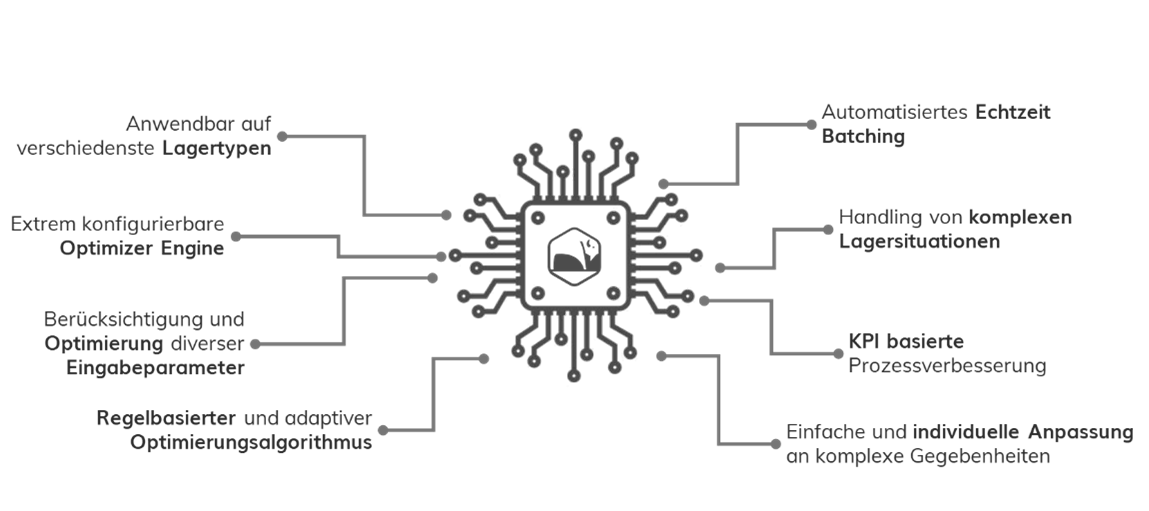

The bisonaire Blending Solution calculates global solutions for complex planning puzzles by means of a highly sophisticated optimization algorithm, which combines and considers the individual objectives of all the above-mentioned focal points. The following planning decisions are made, which can also be made individually and software-supported (semi-automatically) by the planner.

Batch planning

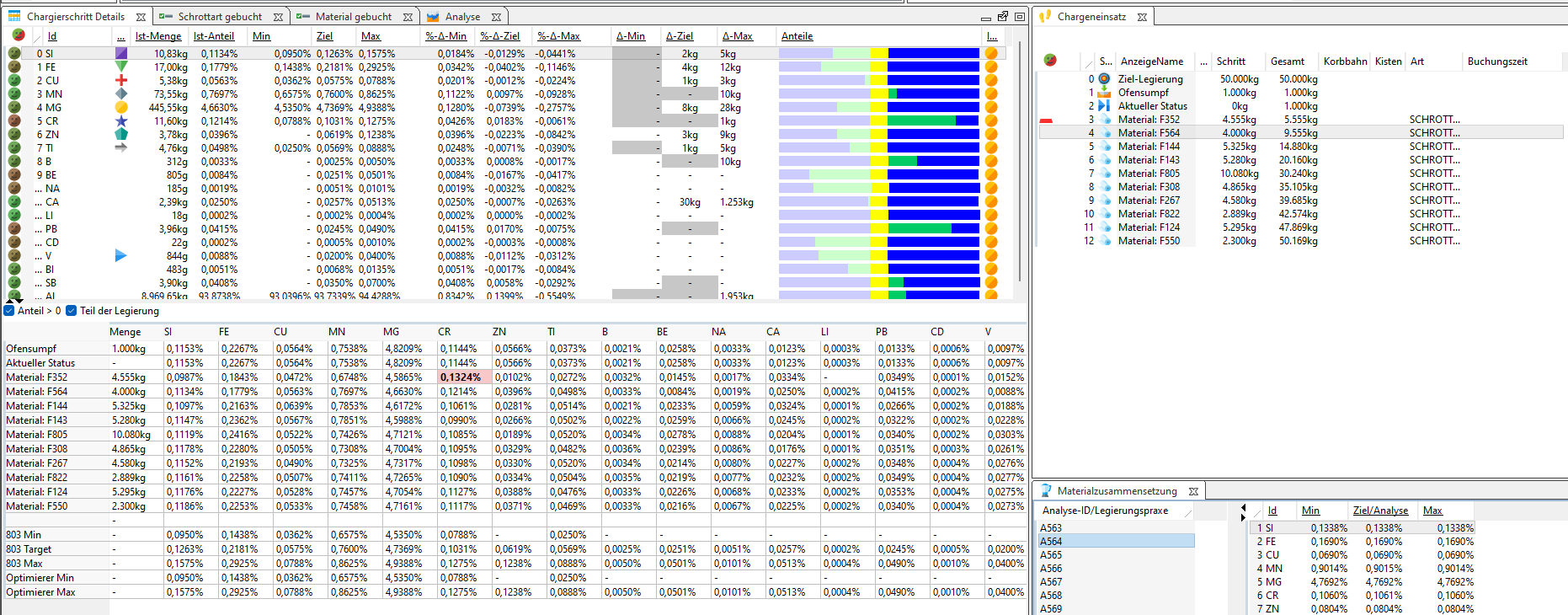

When planning batches, different input data is taken into account:

- Master data from production

- (active) resources / plants

- Plant properties (capacities, …)

- Alloy compositions or recipes

- …

- Composition of the target alloy

- Accessible storage locations / materials

- Stock situation

- Consideration of production-related conditions (e.g. scrap is used via baskets in the furnace)

- …

While most of these restrictions represent hard limits for the optimizer, you can bypass selected basic conditions during manual planning to provide more flexibility. Regardless of how you plan, the system shows you the calculated analysis of your batch for each planning step to provide maximum transparency in planning.

JIT warehouse optimization

Beyond batch planning, the bisonaire Blending Solution supports your decision-making process for the storage of specific scrap or input materials. According to predefined rules and target values, our product can optimize your warehouse situation in such a way that input materials are available more quickly, are stored in a sorted / grouped manner or are optimally distributed across several storage areas. This optimizer runs passively in the background and does not have to be triggered manually, but can be triggered automatically by the receipt of a new input material.

Direct scrap input

In order to save time and ways, the warehouse optimizer, which is active in the background, is not only able to distribute your input materials optimally over all warehouses, but can also decide for each input material receipt whether the material can be directly inserted into an active batch. Depending on individually configurable parameters in the decision-making process, unnecessary transport routes in and out of the warehouse can thus be avoided.