CO2 reduction programmes – who is affected?

Greenhouse gas emissions in the EU will be reduced by 55% (compared to 1990) until 2030.

In the “Fit for 55” package, trading in emission allowance is the central element, because besides energy producers, also industries such as cement, aluminium, fertilisers, electricity, hydrogen, iron and steel, as well as some precursors and a limited number of downstream products, are obliged to participate in emissions trading.

In a nutshell: Every company that operates an energy-intensive industrial plant will be affected by necessary CO2 reductions by 2034.

The free allocation of emission allowances will progressively expire starting in 2026, until no more free allowances are allocated in 2034. In addition, the prices per emitted tonne of CO2 are rising from €25 (2021) to €89 (May 2023) and further.

Therefore, it is particularly important for your company to take CO2-efficient, sustainable actions quickly and effectively.

You can reduce your CO2 emissions with the help of bisonaire through the integrated planning of your order-to-cash process. Even before your company suffers major losses due to the high costs of emission allowances and rising energy prices.

“In cooperation with bisonaire, we succeeded in saving 500,000 tonnes of CO2 per year” – AluNorf

Without saving the 500,000 tonnes of CO2, there would be a loss of approx. €44.5 million for emissions (according to the current allowance price and passed on CO2 costs resulting from the supply chain – tendency: increasing).

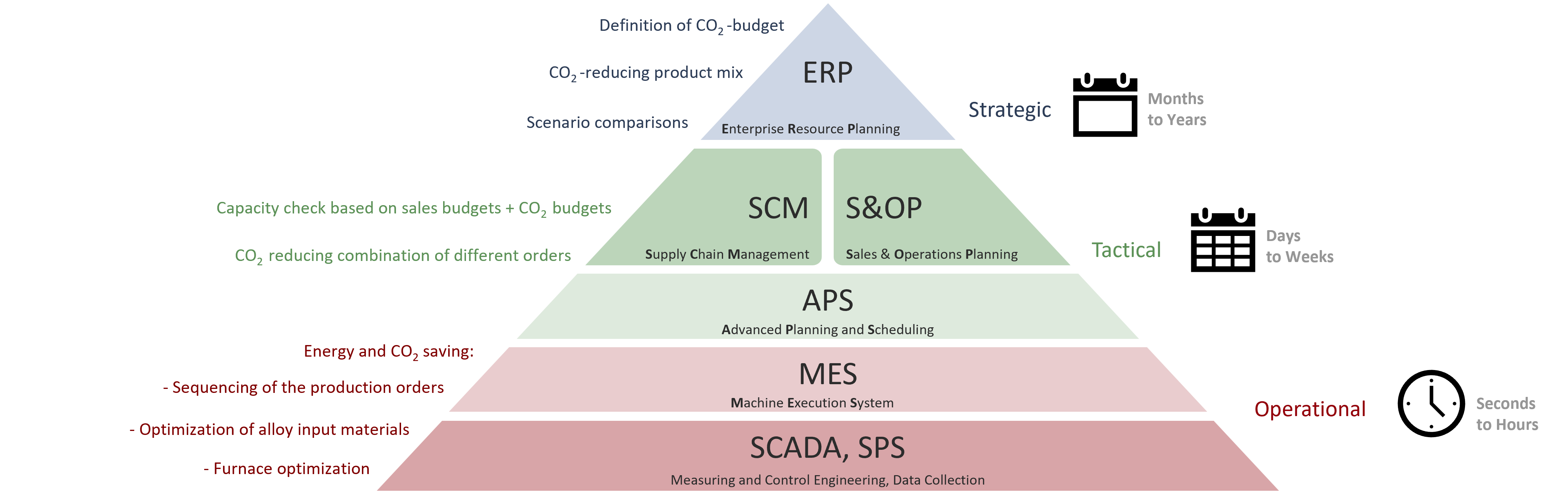

How do planning solutions support your company in meeting the requirements of CO2 reduction targets? – Strategic planning level

Take a look at the company “Ideal”. “Ideal” is an aluminium rolling mill and produces aluminium strips and plates for further processing.

Due to rising prices of CO2 emissions (“allowances”) and high energy costs, “Ideal” has aligned its corporate strategy towards emission restrictions and CO2 reductions.

Strategic planning level

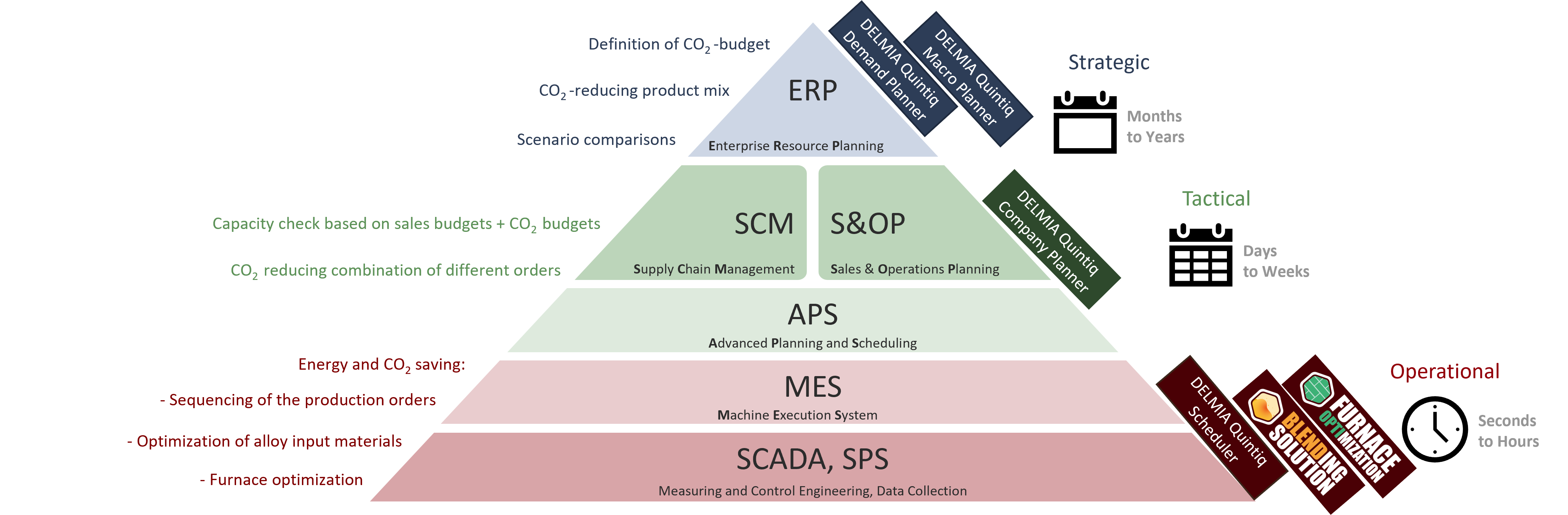

On a strategic planning level, “Ideal” uses planning solutions from bisonaire and partner systems in order to plan the sales volume based on a CO2 -friendly product mix. In this way, orders with lower energy consumption can be prioritized in sales planning and CO2-budgets can be set in addition to sales budgets.

On the strategic level, the question “How much CO2 will we produce in the upcoming months?“ is already answered.

Additionally, “Ideal” uses the intelligent planning solution of scenario simulations, in which different scenarios are compared in order to optimise individual parameters. This allows us to optimise duration, costs and CO2 emissions individually and to track the effects one parameter has on the others. “Ideal” thus knows that a particularly fast handling of ist manufacturing processes is associated with high CO2 emissions and can therefore choose to optimise the parameters long-term to reduce CO2 emissions.

Tactical & Operational planning level

Tactical planning level

On a tactical level, “Ideal” also creates a CO2 reduction in medium-term rough planning through parallel planning of orders in Sales Budgets/C02 Budgets. Orders are checked and assigned to others with similar oven temperatures so that the heating processes for different products match. Heating the ovens causes extreme energy consumption and high CO2 emissions. CO2 can therefore be reduced by tactically planning the orders while additionally more precise reporting back to the customer is provided.

Operational planning level

Also at the operational level, “Ideal” uses suitable planning tools to achieve energy efficiency and CO2 reduction, by optimising the production sequence, material properties and changes of alloy types in the scheduler.

This optimised operational planning is enhanced by using the bisonaire Blending Solution and Furnace Optimiser and therewith greatly improving the production.

For casting of ingots, the Blending Solution searches for proper scrap as input materials for the alloy, so that only a small amount of pure material is needed. In doing so, the costs for pure materials, partial overpasses, emergency castings and CO2 allowances (high emissions that would occur through the use of pure material – pure material causes significantly more CO2 than recycled scrap due to its manufacturing process) are already saved in the initial production steps.

After the ingot has been cast, milled and rolled in the factory of „Ideal“, the aluminium plates are now ready for further processing in furnaces. The optimisation of the furnaces also has a large impact on the lowering “Ideal’s” emissions. Therefore, “Ideal” uses the bisonaire Furnace Optimizer, which plans the optimal utility of the furnaces.

Various parameters such as furnace size, annealing time and temperature are taken into account. This allows to form intelligent batches for the furnace so that, for example, the entire capacity of the furnace is exploited and the heating phase of one batch can be used to process another. The Furnace Optimizer makes it possible to save CO2 and energy.

Are you and your company equipped to meet the requirements?

Monetary losses due to high emission allowance costs and rising energy prices will also affect your company in the coming months and years.

Is your company prepared for the rising CO2 costs and more expensive emission allowances?

With bisonaire’s integrated planning approach you can profitably implement your CO2 requirement reduction.

Beyond preventing monetary losses, by reducing CO2 demand you also create the opportunity to participate in emissions trading and make profits through the sale of allowances.